Conveyor belts hot press machine

Introduction

Introduction

PVC & PU conveyor belt hot-press splice machinealso known as belt hotpressing machine, belt splicer, belt

jointing machine, vulcanizing machine,vulcanizer however, it is a kind of specialized equipment which use

hightemperature, certain pressure and cooling technology, to splice the PVC, PU, orPE material belt.

Featuresand Benefits:

01. Durable structure design

Use the stainless steel and the highstrength alloy steel material to manufacture, the structure is not easy tocurve

under high atmospheric pressure.

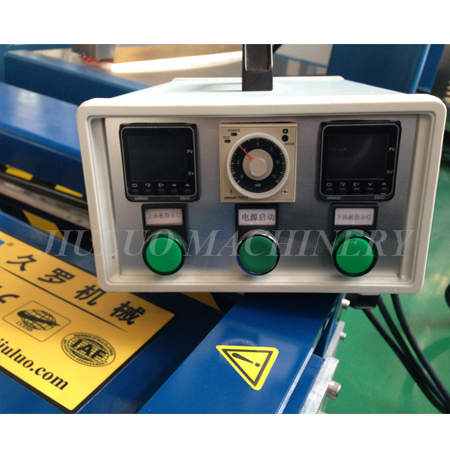

02. D.T.C Precise temperaturecontrol system

D.T.C technology can achieve theprecious control of heating temperature

The suggestedmaximum heating temperature is 210 degrees (Celsius)

Upper and lower plate heating mode, heating from 0 - 180 degrees, about 20 minutes(depends onambient

temperature).

03. Using atmospheric pressure to work

Durable two - tierstructure airbag, designed for long-term use.0--2.5kg/cm2 adjustable atmospheric pressure,

easy tooperate.

04. Rapid water-cooling system

Water-cooling, coolingfrom 180 degrees to 60 degrees??Celsius), or 340 degreesto 140 degrees(Fahrenheit),about 6 - 10 minutes(depends on the length of themachine).

05. User-friendly design for operation

Equippedwith automatic control cabinet, which can be used to pre-set temperature,automatic heat, automatic temperature control, automatic start water cooling.Designed to be easily assembled or disassembled, easy to maintain.