Ply separator

Introduction

Introduction

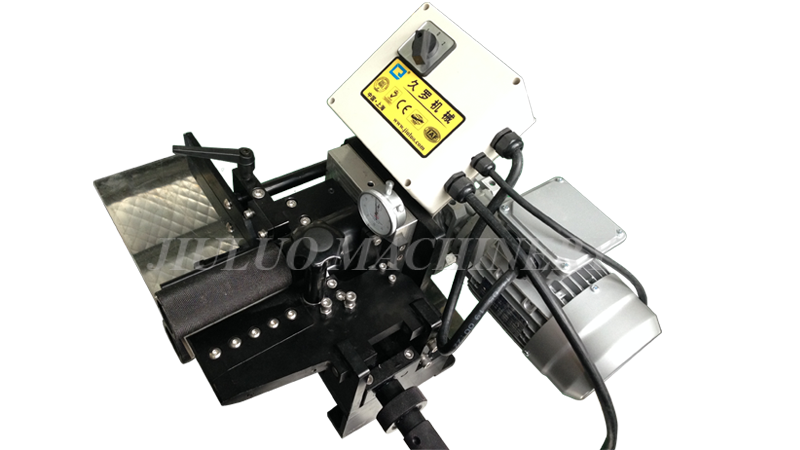

Belt ply separator (belt splitter, belt splittingmachine)

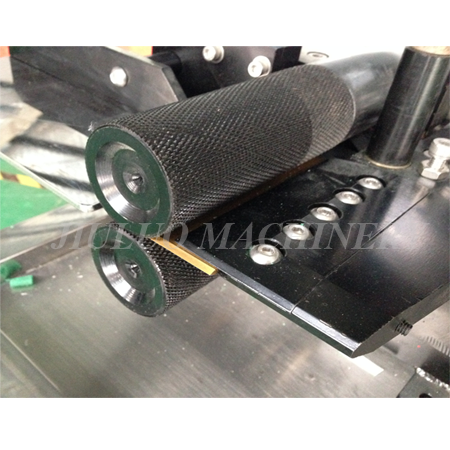

The separator is used to cut in between theplies of a conveyor belt. This cutting action is often required in

preparationbefore splicing a belt with a splice press. A great advantage of this plyseparator is that it can

split as deep as 130 mm in one action. This isespecially helpful when splitting very thin belts or belts where

the materialis difficult to cut, like thin PU belts.

A. Features and Benefits

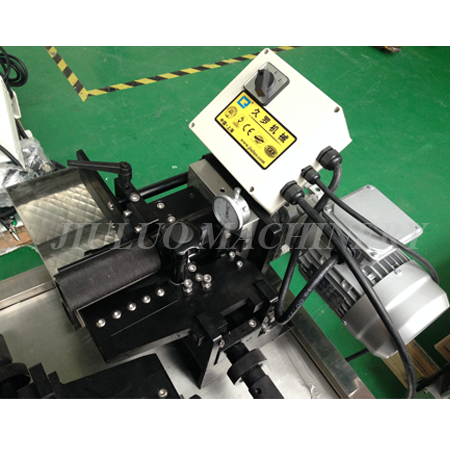

1. Durable structure design

key mechanical components are heat-treated

2. Running speed at 6.5meters/min

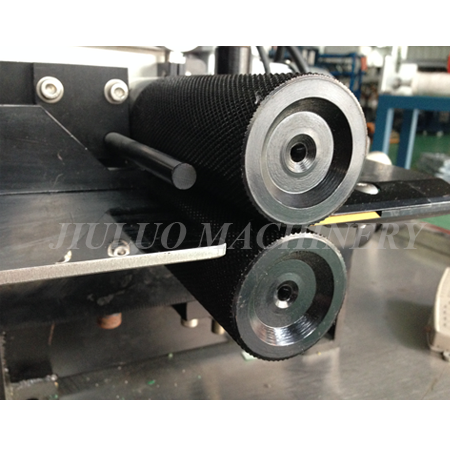

3. Suitable for 1-10 mm thicknessconveyor belt

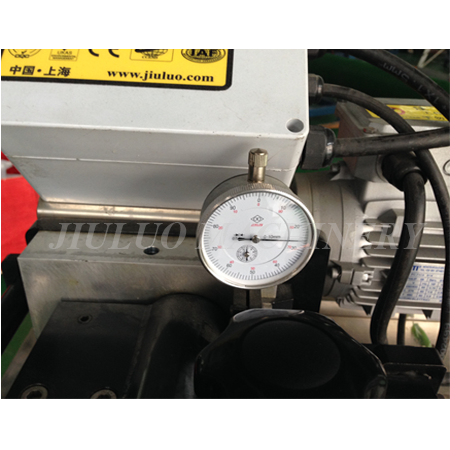

May accurately adjust theknife position, including the direction of up and down, front and rear.

4. Forward & reverse pedalcontrol

5. Voltage applicable all over theworld

The operating voltage canbe modified to 380V or 220V,according to customer''s requirement

B. Technical datas:

Layering blade: Hard alloy steel blade

Controller: Positive & negative turn control box

Switch: Footpedal

Voltage: 380V,3AC, 50/60HZ

Power: 750W

Splittingthickness:1-15mm, PVC conveyor belts.

4. Note:

Model | JL-750 |

Machine length | 710mm |

Machine width | 550mm |

Pressure way | Pneumatic |

Net Weight | 95KG |

Max. Ply depth | 120mm |

Min ply thickness | 0.8mm |

1. This equipment is used for belts splitting,cut thick belt into thin belt .

2. Belts can be divided into twolayers, three layers, or four layers, etc

3. Layered thickness accuracycan reach 1 mm